The development and use of new materials have improved safety and affordability in the aerospace and automotive industries. Scientists are working to apply similar principles to the development of new materials for nuclear energy in order to extend reactor lifetimes and increase accident tolerance. Materials utilized within reactors face a variety of challenges, including the critical ability to withstand high radiation at high temperatures. A team of university and U.S. national laboratory researchers working at the U.S. Department of Energy’s (DOE’s) Advanced Photon Source (APS)and other DOE facilities at Argonne National Laboratory developed and demonstrated preliminary results for a new technique for evaluating fuel and reactor materials. This technique, which requires less time and expense than current techniques, involves irradiating potential materials with high-energy, atomic nucleus ions and then assessing the damage using synchrotron x-ray diffraction and electron microscopy.

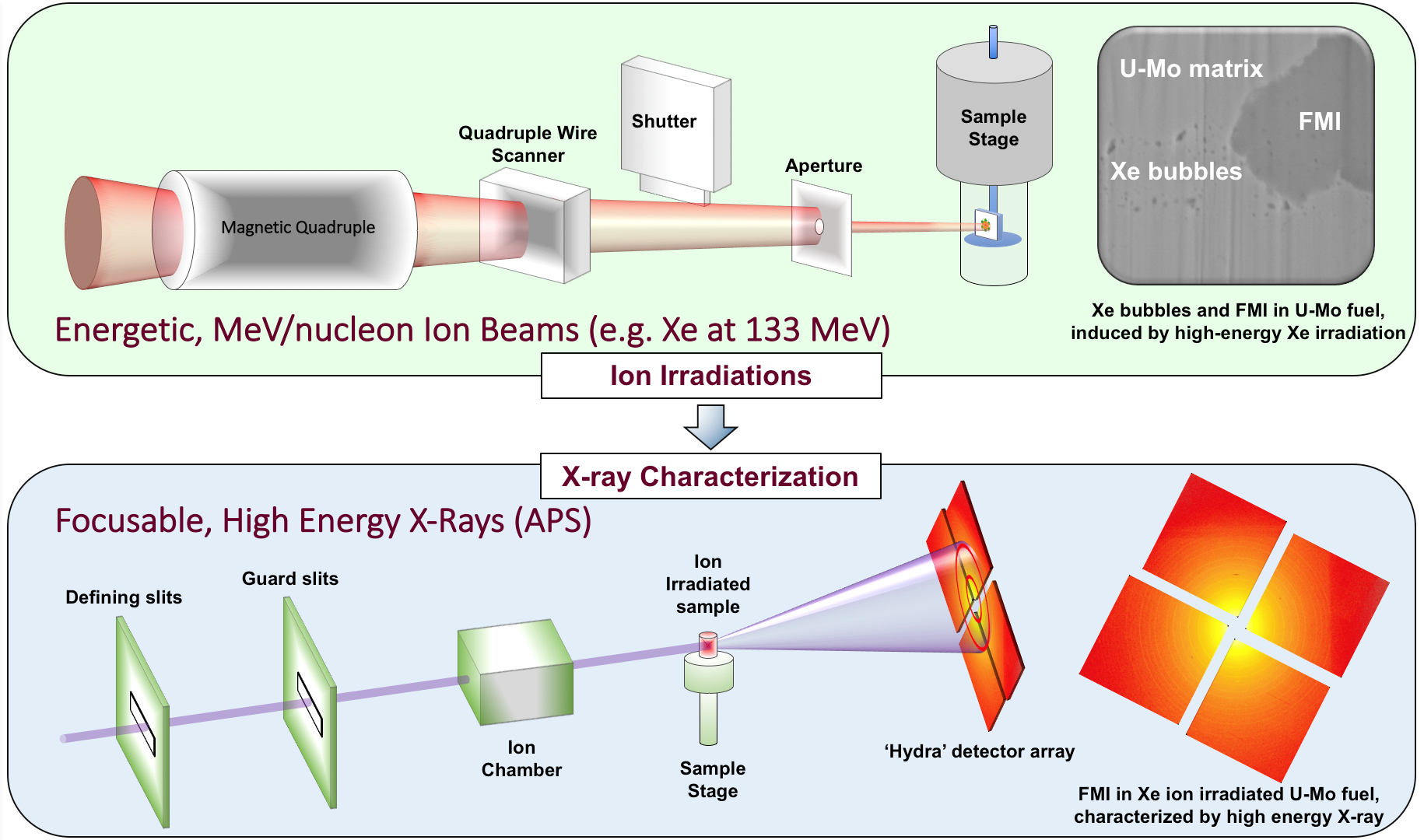

Unlike alternative energy sources such as wind and solar, nuclear energy is neither intermittent nor variable. To provide this consistent energy, nuclear reactors are utilized to power turbine generators with the heat produced by the nuclear reactions of the fuel. But the structural materials of the reactor and the fuel itself must be able to withstand the high-temperature and high-pressure environment that occurs during the radioactive decay or nuclear reaction of the fuel. Historically, testing new materials involves low irradiation dose rates over a long time and requires expensive precautions post-irradiation to handle the radioactive materials. To avoid these difficulties, the team from Argonne and Northwestern University proposed a two-step technique. Figure 1 shows a cartoon diagram of the equipment used for irradiation and characterization, as well as a picture of an irradiated fuel sample. The irradiation was performed at Argonne’s ATLAS accelerator to simulate damage from high-energy fission fragment ions, replicating the effects of years of reactor exposure in a matter of days at ATLAS.

The team assessed two types of materials with this technique. The first was two variants of uranium-molybdenum fuel: U-7Mo, which is 7% molybdenum by weight, and U-10Mo, which is 10% molybdenum by weight. Other researchers have investigated these fuels because they were developed to convert high-performance research reactors to the use of low-enriched uranium, so these materials are of high interest to the research reactors community. The second material was HT9, a ferritic-martensitic steel to be used as fuel cladding material in advanced reactors. The U-7Mo was irradiated at ATLAS with 84-MeV Xe26+ ions and the U-10Mo was irradiated with 105-MeV Xe26+ ions. The HT9 samples were irradiated with 84-MeV Fe26+ ions.

To assess the materials' response to the radiation, the samples were cut to reveal a cross section of the damage. Then the team used high-energy x-ray diffraction on the X-ray Science Division (XSD) 1-ID-B,C,E beamline and microbeam Laue diffraction at the XSD 34-ID-E beamline—both at the APS—to assess the damage. The APS and ATLAS are DOE Office of Science user facilities.

They found lattice strain to a depth of approximately 6 µm in the U-10M fuel sample. Assessing the damage to a sample of U-7Mo fuel utilizing scanning electron microscopy and transmission electron microscopy at Northwestern and at the Argonne IVEM-Tandem Facility, a DOE Office of Nuclear Energy facility, the team also found build-up from the interaction between the fuel and its holding matrix, which is similar to what is found due to irradiation in a reactor and limits the performance of this type of fuel.

The team obtained only preliminary results for the HT9. Based on the synchrotron x-ray diffraction data, peak ion damage occurred approximately 4 µm beneath the sample's surface. However, transmission electron microscopy results indicate the damage may have penetrated deeper. The lack of significant grain growth in the irradiated area indicates damage is mainly a function of an increase in crystallographic irregularities within the sample (an increase in dislocation density).

The team's results allow them to conclude that irradiation by energetic ions coupled with synchrotron x-ray diffraction analysis is indeed a useful technique for assessing the damage incurred by nuclear fuels and structural materials, and should be used during the future development of new reactor materials. This new technique allows for spatially resolving the damage to reactor-related materials through use of an analogue for the conditions in the reactor environment, and should expedite the research and testing cycle of new materials for nuclear energy.

Additionally, this work provides the technical basis for the XMAT (eXtreme MATerials) beamline for the proposed Advanced Photon Source Upgrade. This beamline is aimed at developing new and more capable radiation tolerant materials for nuclear environments.

— Mary Alexandra Agner

See: M.J. Pellin, Abdellatif M. Yacout, Kun Mo, Jonathan Almer, S. Bhattacharya, Walid Mohamed, D. Seidman, Bei Ye, D. Yun, Ruqing Xu, and Shaofei Zhu, “MeV per nucleon ion irradiation of nuclear materials with high energy synchrotron X-ray characterization,” J. Nucl. Mat. 471, 266 (2016). DOI: 10.1016/j.jnucmat.2016.01.004

Correspondence: *[email protected]

This work was supported in part by the U.S. Department of Energy (DOE) Office of Science-Basic Energy Sciences under Contract No. DE-AC02- 06CH11357. This research used resources of the Argonne ATLAS facility, which is a DOE Office of Science User Facility, and the Argonne-Tandem Facility, a OE Facility funded by the DOE Office of Nuclear Energy, operated under Contract No. DE-AC02-06CH11357 by UChicago Argonne, LLC. This work was supported by the U.S. DOE Office of Global Threat Reduction (NA-21), National Nuclear Security Administration, under Contract No. DE-AC-02-06CH11357 between UChicago Argonne, LLC, and the DOE and Argonne strategic Laboratory Directed Research and Development program. This work made use of the EPIC facility (NUANCE Center- Northwestern University), which has received support from the MRSEC program (NSF DMR-1121262) at the Materials Research Center; the Nanoscale Science and Engineering Center (NSF EEC- 0647560) at the International Institute for Nanotechnology; and the State of Illinois, through the International Institute for Nanotechnology. This research used resources of the Advanced Photon Source, a U.S. DOE Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02- 06CH11357.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC for the U.S. Department of Energy's Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.