08.13.2014

Raloxifene, a treatment for decreasing fracture risk in osteoporosis, works only partially by suppressing bone loss. Studies at the U.S. Department of Energy′s Advanced Photon Source revealed an add...

1-ID-B,C,E

12.10.2014

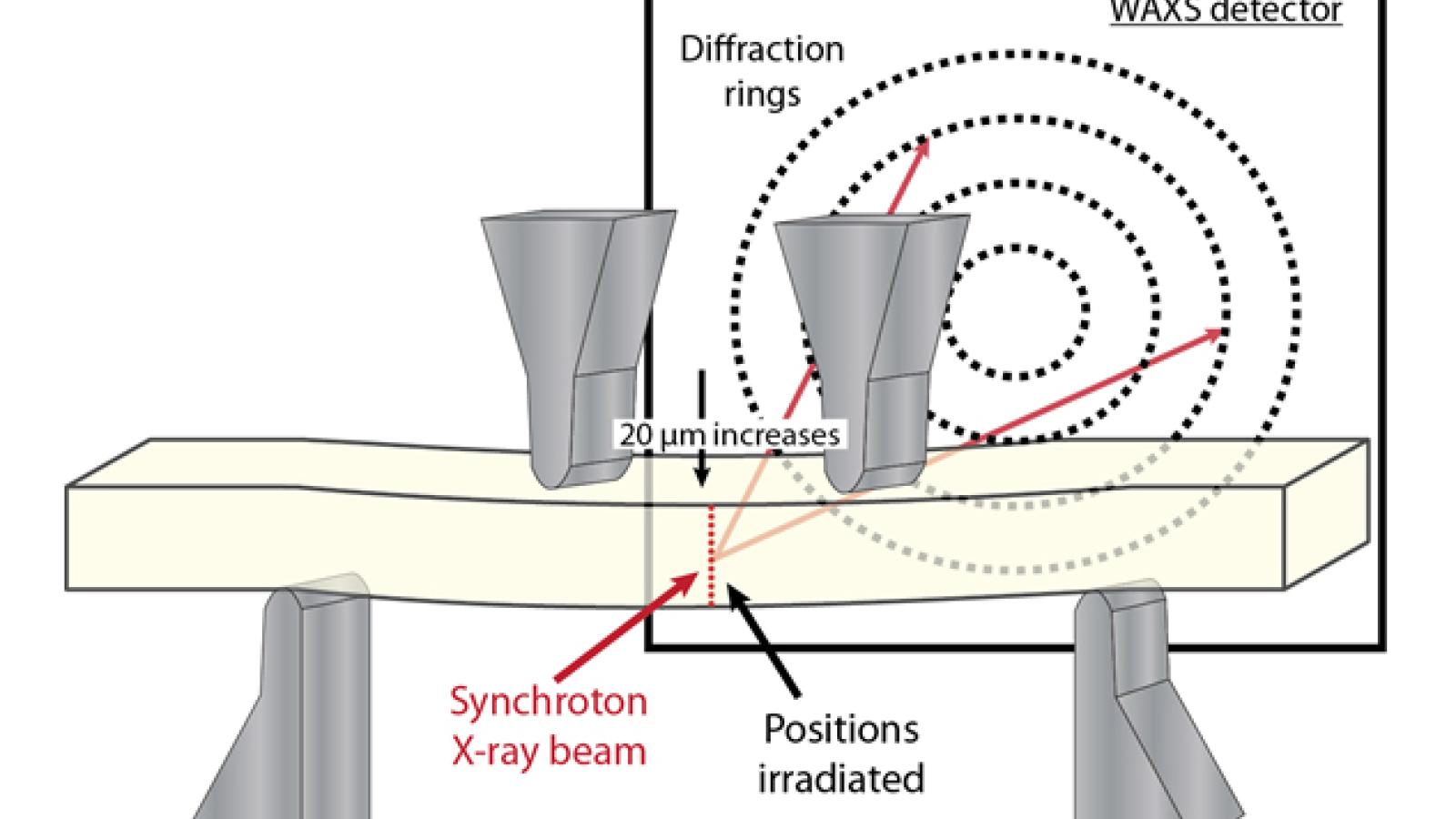

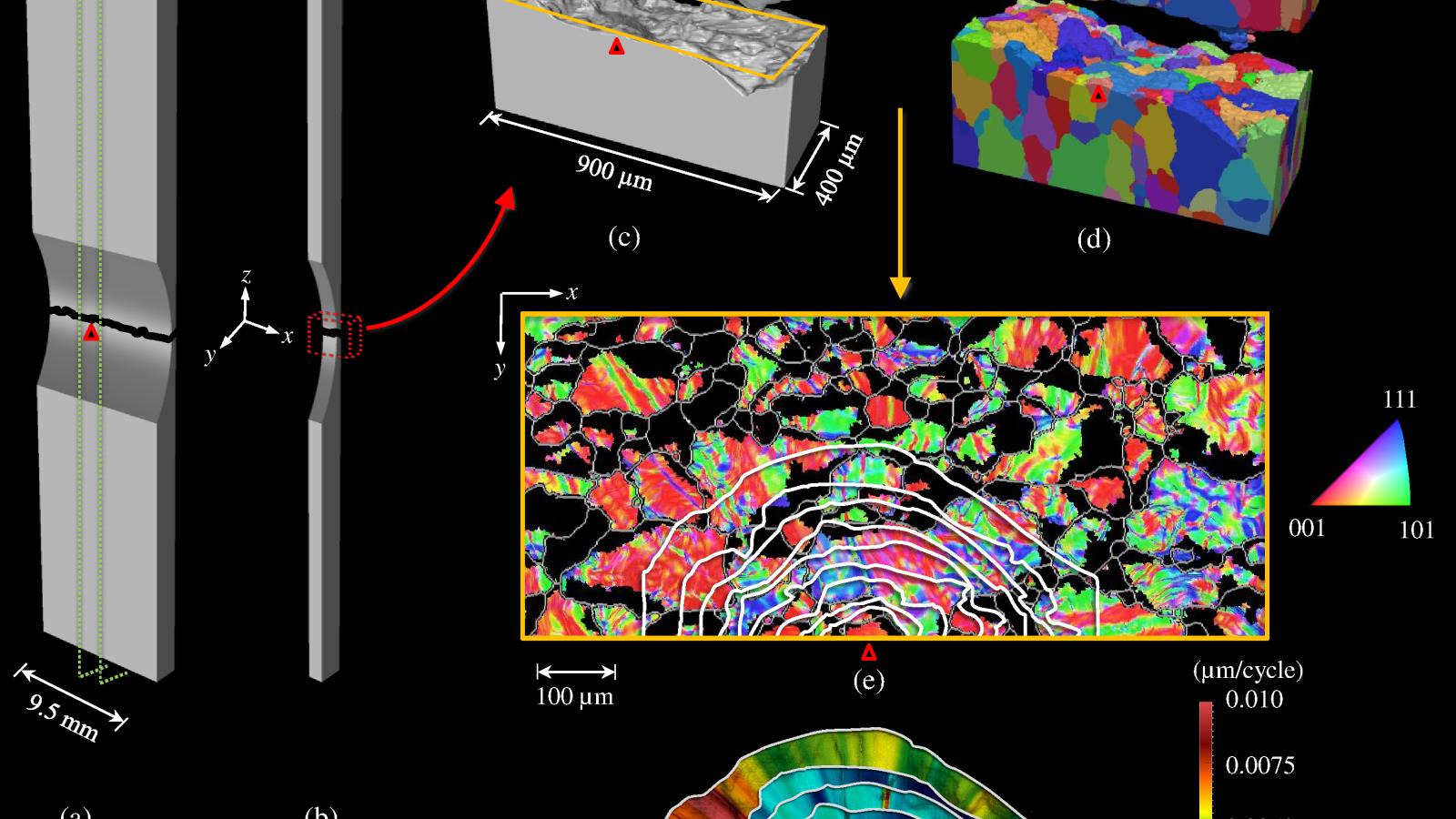

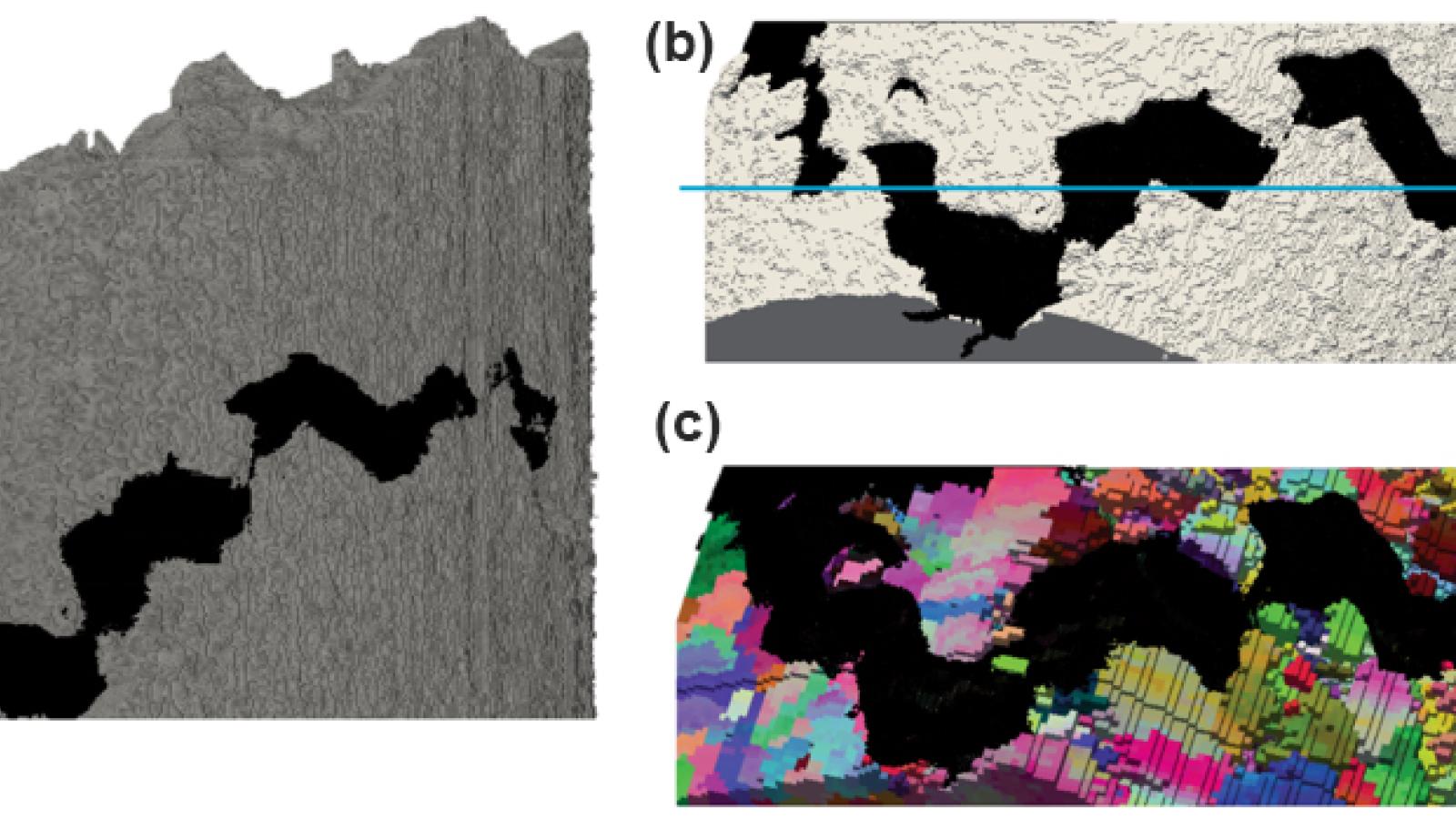

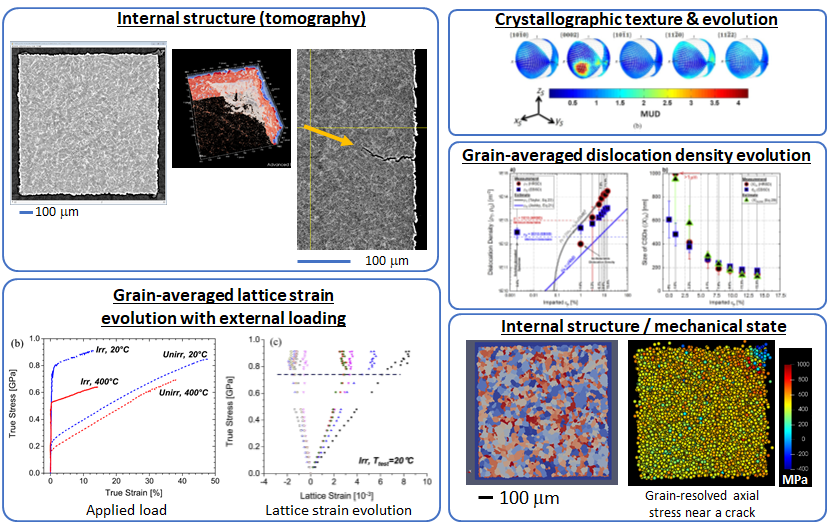

Understanding how cracks spread through a material is important for predicting how long a structure might last before breaking, as well as for designing new materials more resistant to failure. Resear...

1-ID-B,C,E

12.15.2015

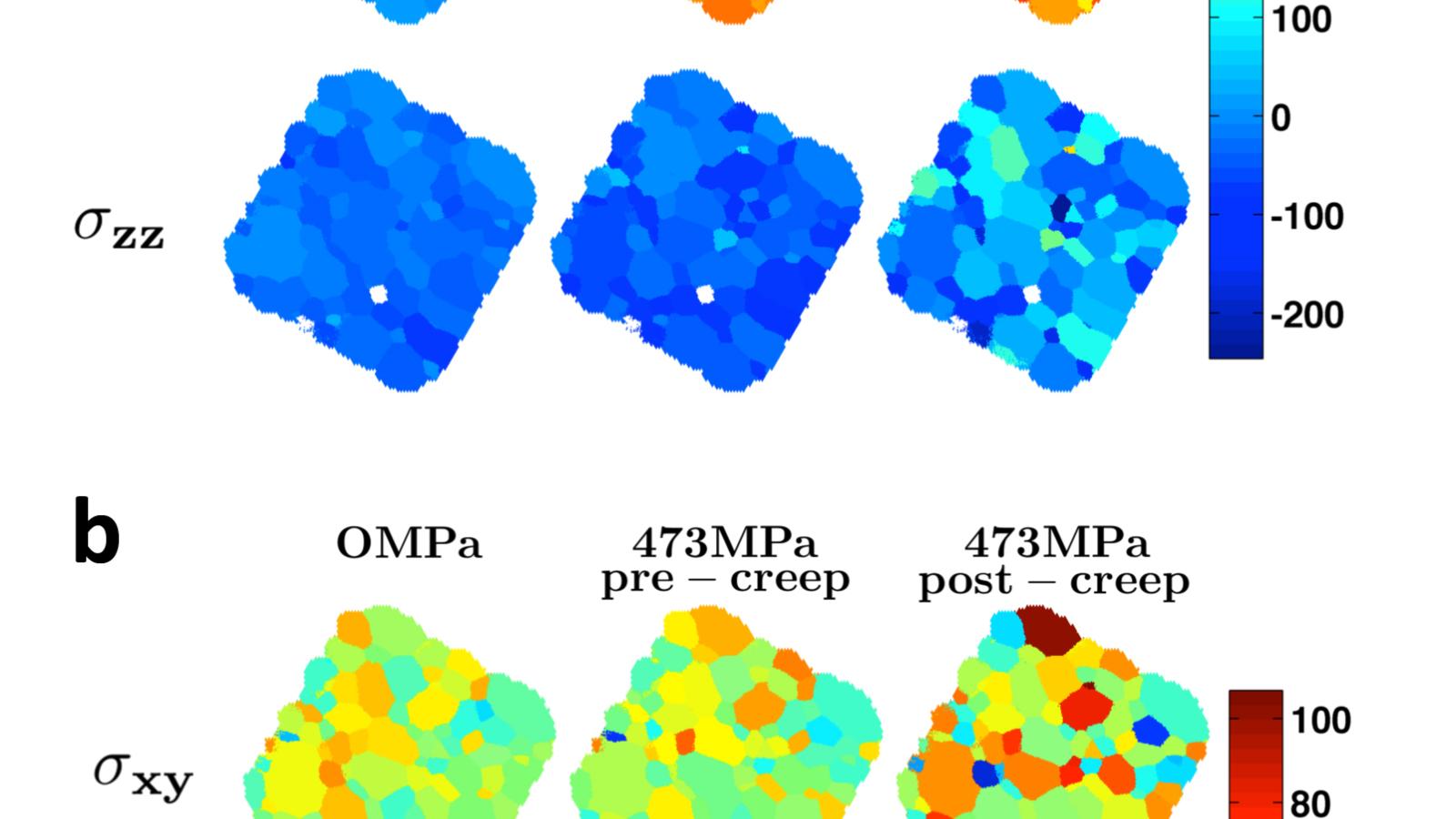

The smooth, metallic surface of a titanium golf club head hides a messy reality. Though it looks homogenous to the naked eye, the head is actually made of individual grains of metal, of many different...

1-ID-B,C,E

02.04.2016

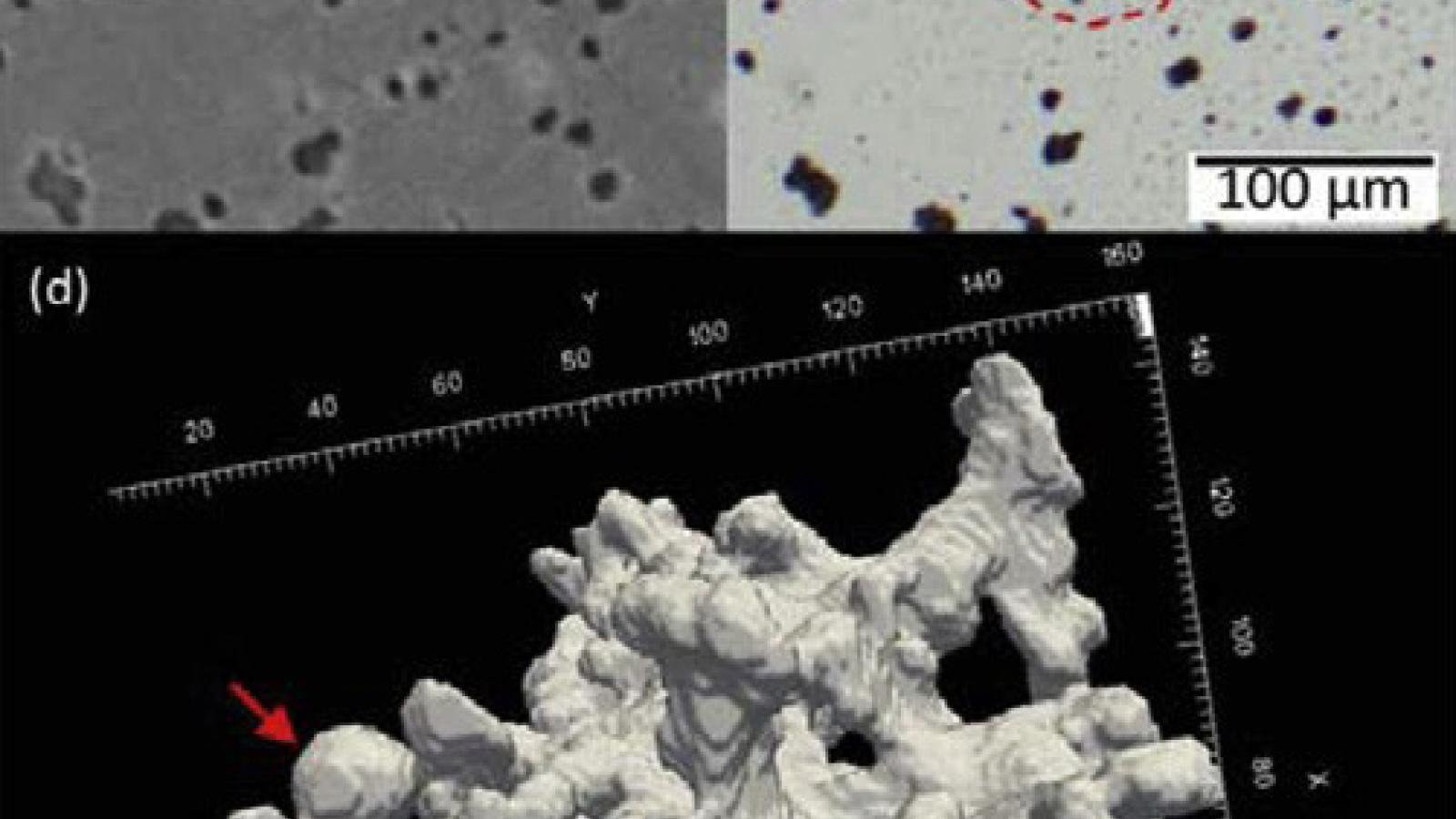

Cast iron is an alloy of iron, carbon, silicon, and other elements with numerous industrial and consumer applications. The carbon content of cast iron — generally higher than that of steel — appea...

1-ID-B,C,E

12.03.2013

Humans have devised many amazing and versatile materials (such as plastic and steel) that do not exist in nature. On the other hand, nature has created structures and substances that materials scienti...

1-ID-B,C,E

03.03.2009

Power plants based on turbine engines burning natural gas are a key component of future energy grids in the U.S. and other nations. With these engines, power plants will supply clean, increasingly fue...

1-ID-B,C,E

10.22.2010

Research at the U.S. Department of Energy’s Advanced Photon Source (APS), Center for Nanoscale Materials (CNM), and Electron Microscopy Center (EMC) at Argonne National Laboratory has provided an un...

1-ID-B,C,E

11.28.2017

APS Group Leader Jonathan Almer, left, takes measurements during an experiment on Monday to study a nearly 2,000 intact mummy that was found in Egypt. The powerful x-ray beams at the APS could shed li...

1-ID-B,C,E

03.06.2018

Titanium is a workhorse metal of the modern age. Alloyed with small amounts of aluminum and vanadium, it is used in aircraft, premium sports equipment, race cars, space craft, high-end bicycles, and m...

1-ID-B,C,E

03.15.2018

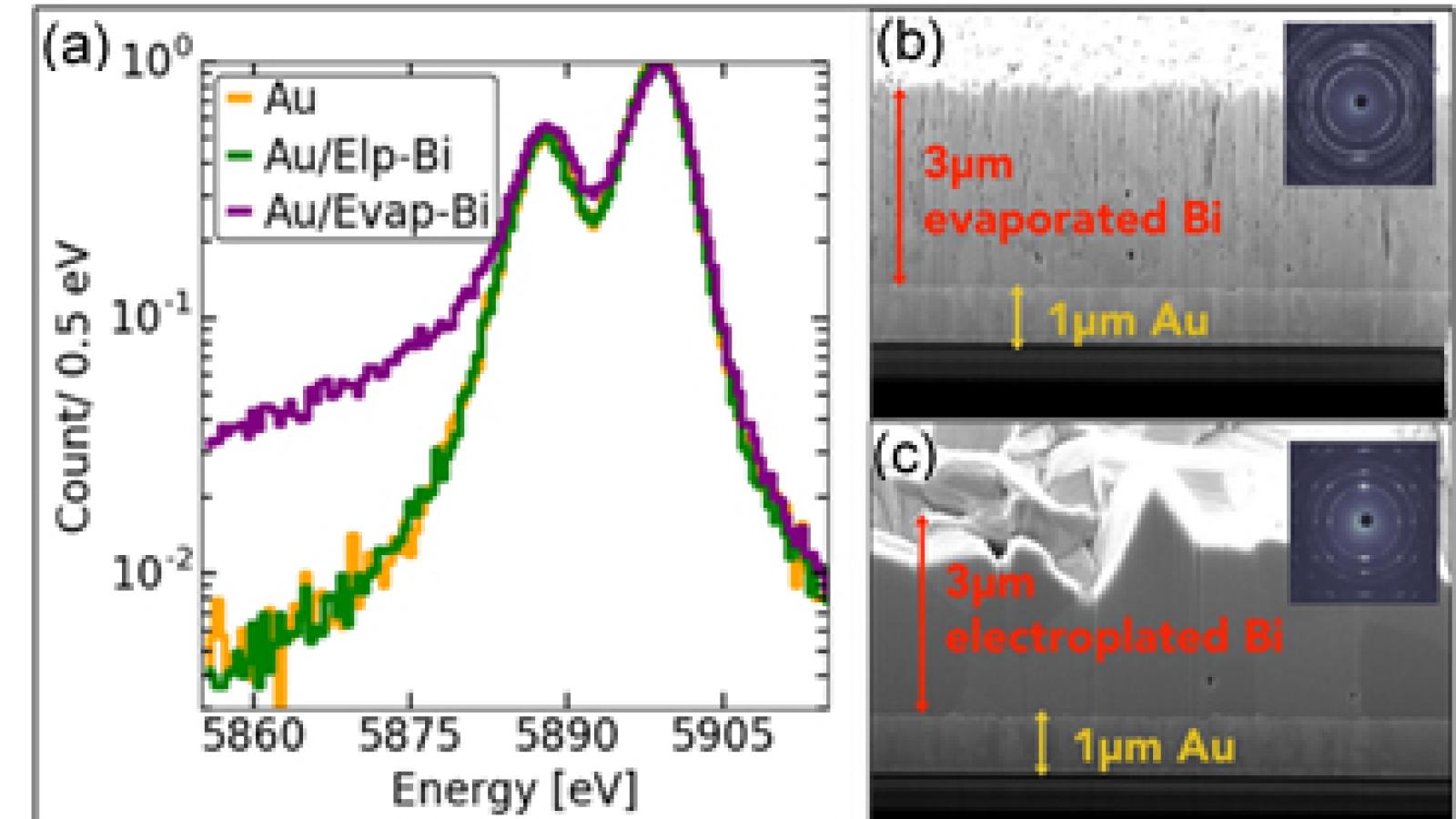

From detecting x-rays from outer space to elemental mapping at the nanoscale, transition-edge sensors (TES) are essential tools for scientific discovery. These devices measure the electrical resistan...

1-ID-B,C,E

09.20.2018

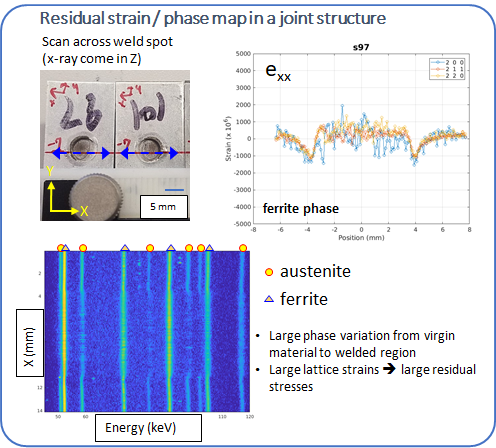

In work that could help prevent the failure of everything from bridges to dental implants, a team of researchers utilized the U.S. Department of Energy’s Advanced Photon Source to obtain the first t...

1-ID-B,C,E

10.24.2018

Although crucial to modern life, metal alloys can fail, possibly leading to bridge collapse or other disasters. One cause of failure about which little has been understood is hydrogen embrittlement, w...

1-ID-B,C,E

06.02.2020

Understanding the primary mechanisms responsible for steel embrittlement caused by H2 exposure should help materials scientists develop strategies to ameliorate this problem, which has important ramif...

1-ID-B,C,E

07.20.2020

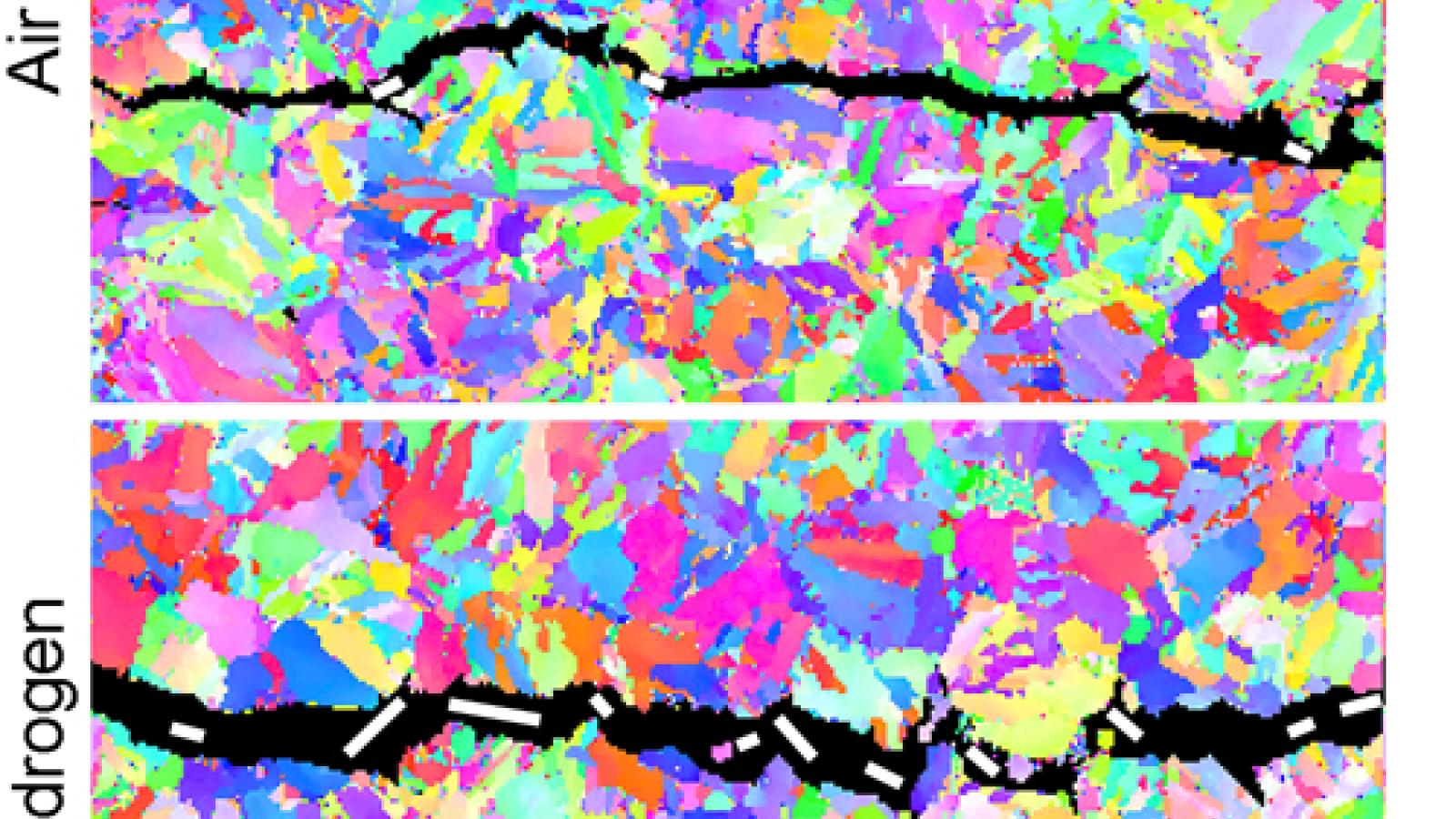

Research at the U.S. Department of Energy’s Advanced Photon Source Stress revealed new information about wave propagation through granular material, which is important for detecting the magnitude of...

1-ID-B,C,E

08.06.2020

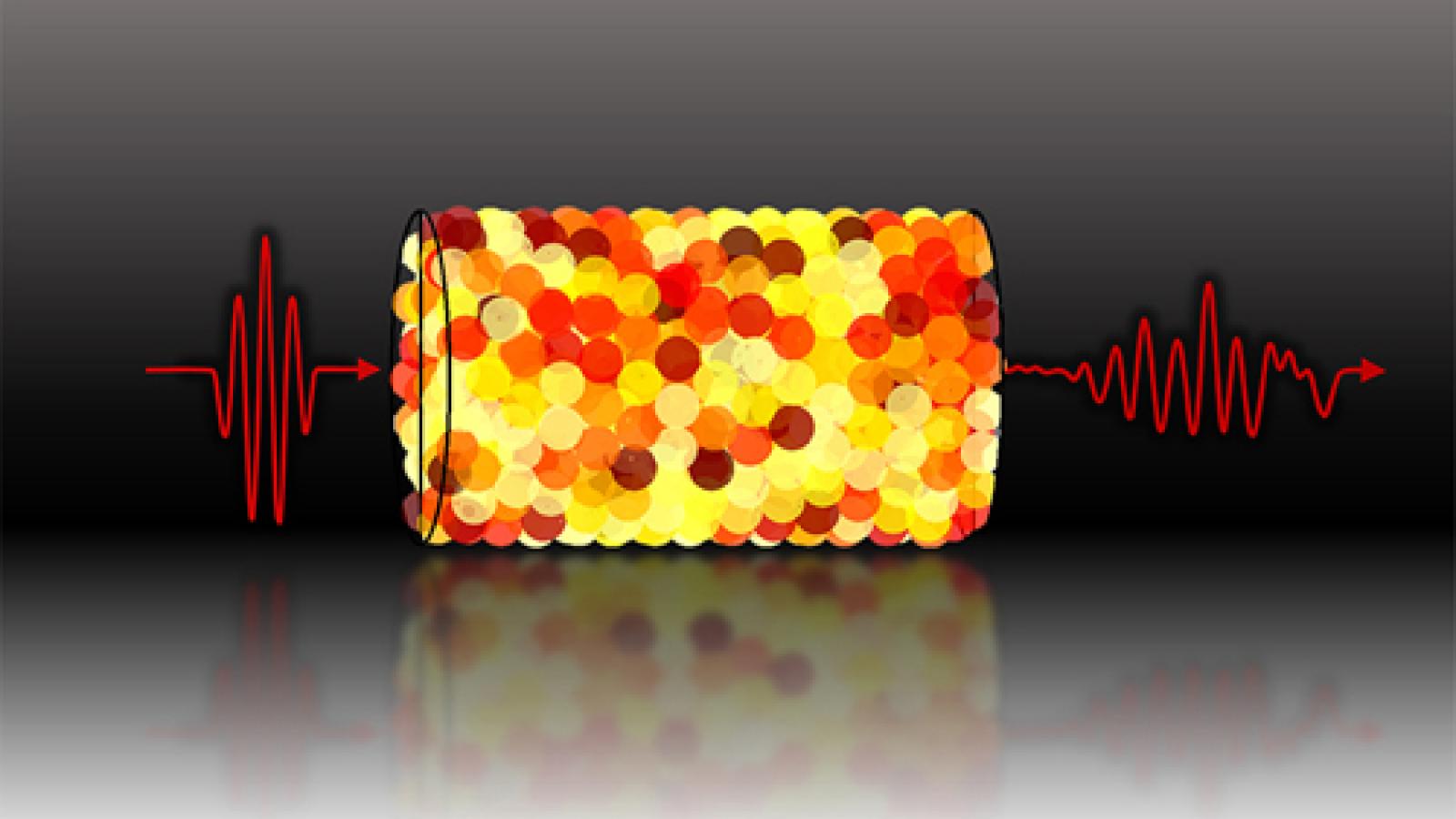

Researchers using the U.S. Department of Energy’s Advanced Photon Source took a detailed look at high-temperature tantalum behavior to assess its role in potential future superconducting, optoelectr...

1-ID-B,C,E, 11-ID-C

06.08.2021

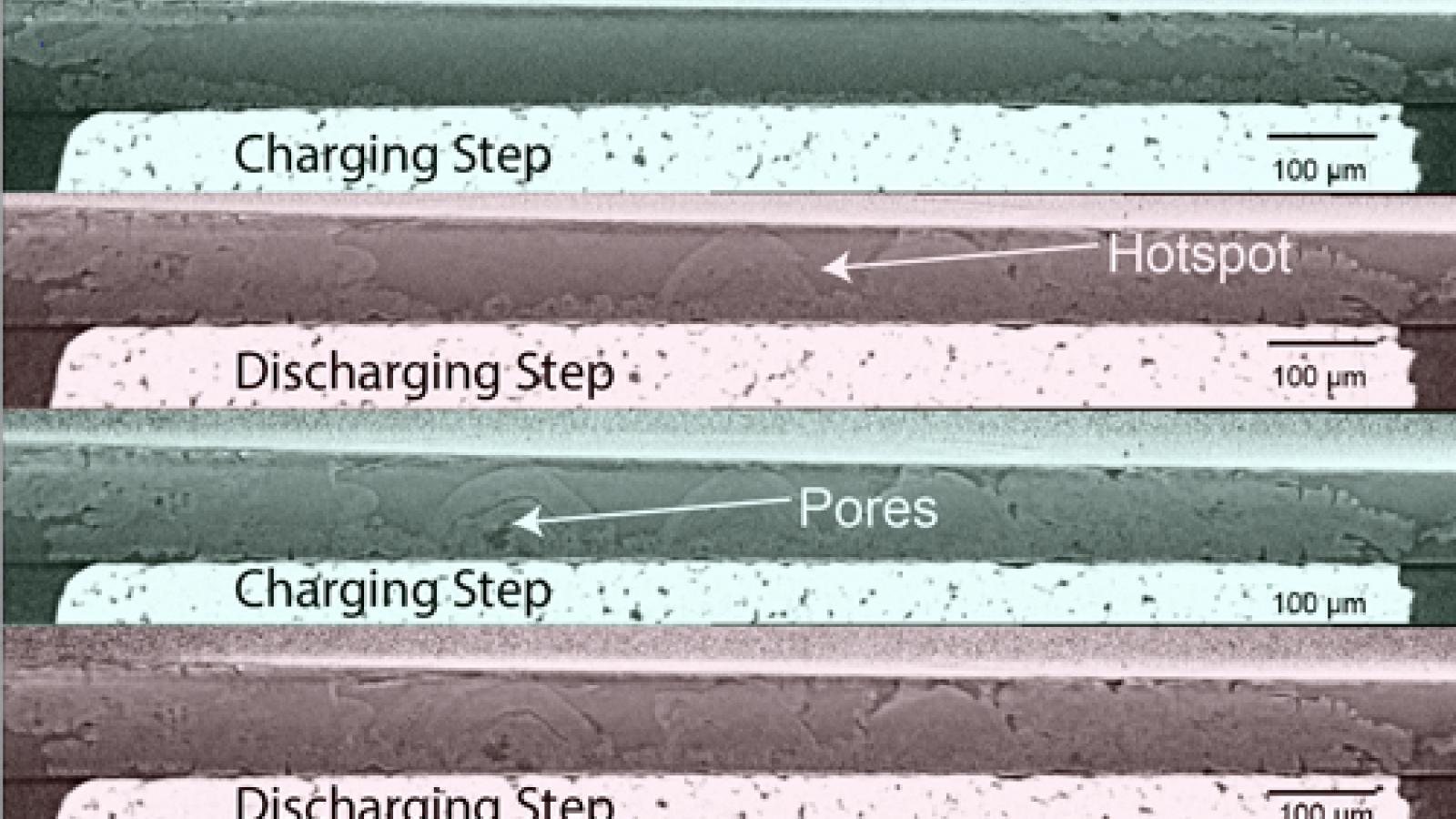

Testing the Mettle of Lithium Metal Batteries: Lithium-based batteries need improvement. Researchers used the U.S. Department of Energy’s Advanced Photon Source to gather information which could le...

1-ID-B,C,E

10.18.2021

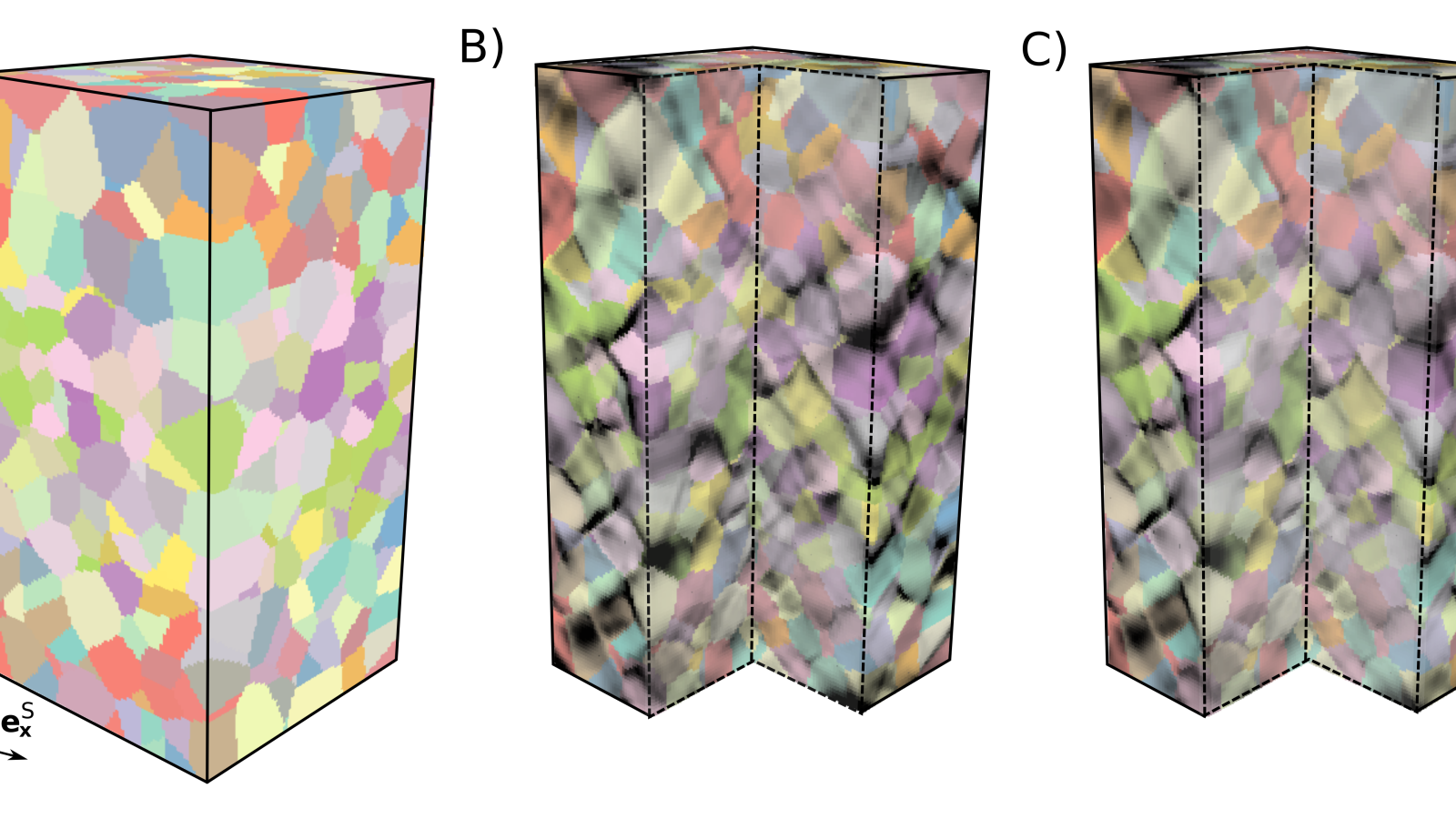

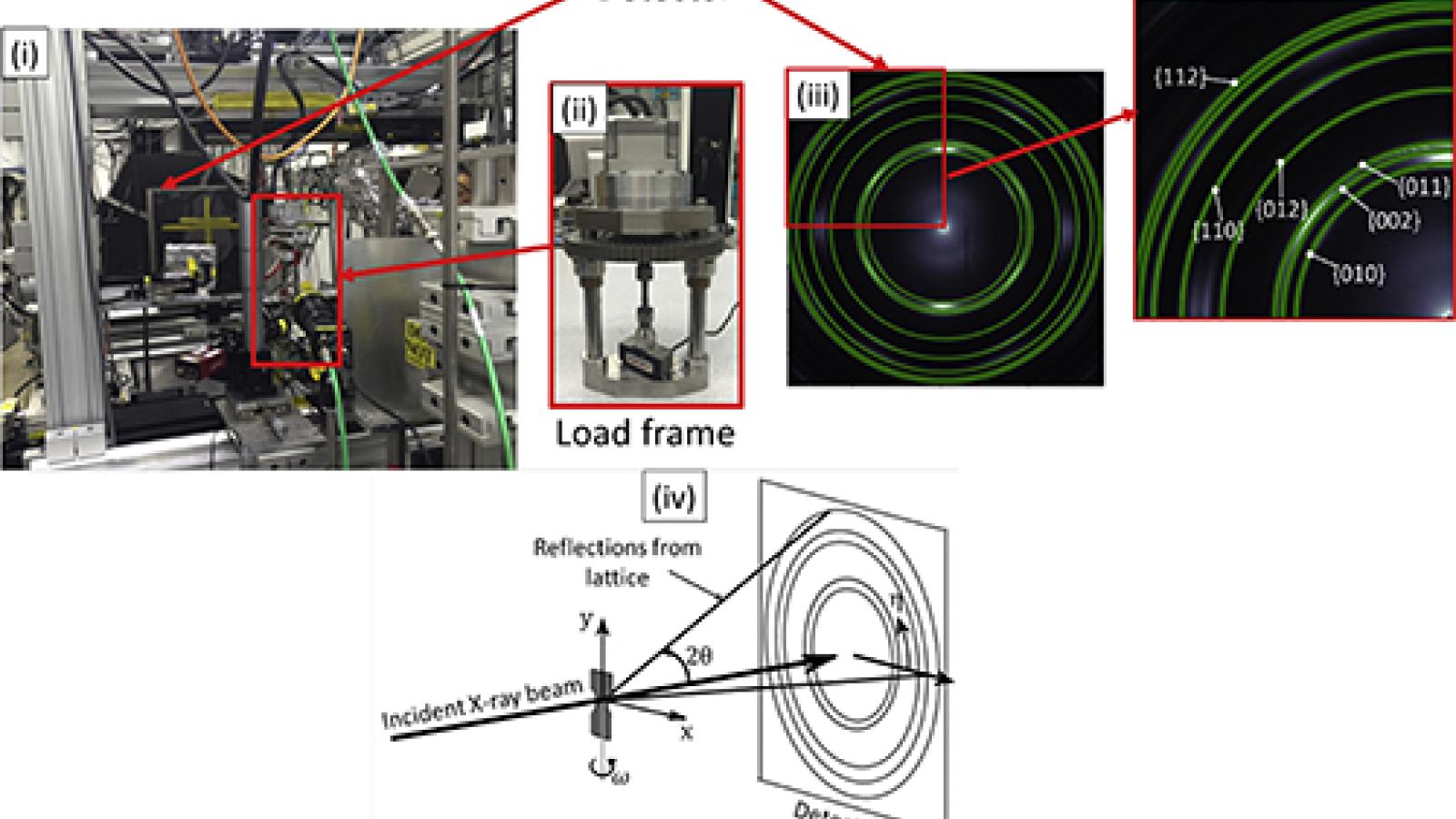

Multi-Scale Experiments Inform Modeling of Titanium Alloy Durability: Titanium alloys have been widely used in the biomedical and aerospace industries for decades, but the mechanisms associated with ...

1-ID-B,C,E

02.22.2022

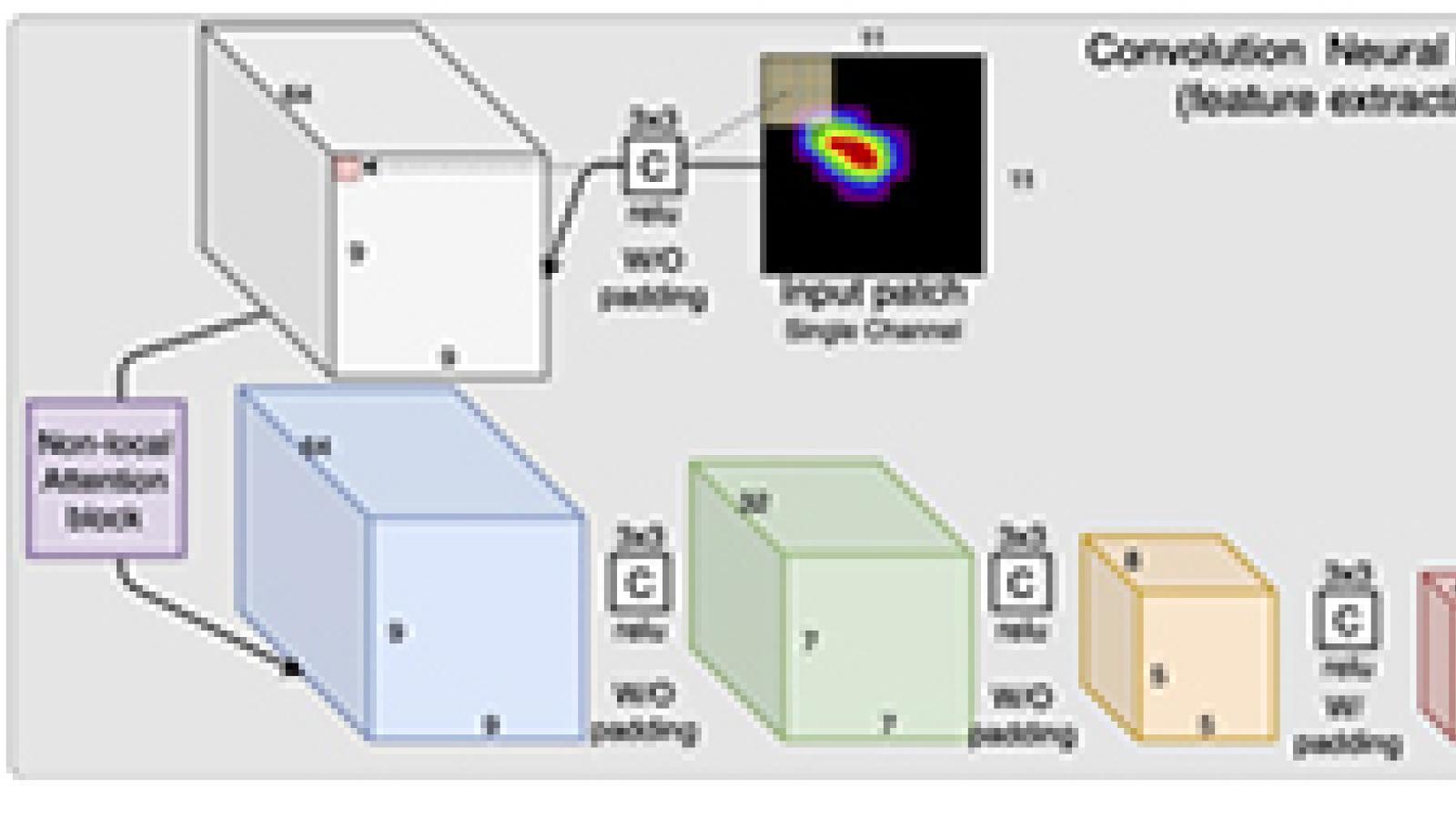

BraggNN: Deep Learning for X-ray Diffraction Microscopy: Artificial intelligence (AI) systems using deep-learning neural networks are revolutionizing many scientific disciplines. Researchers at the...

1-ID-B,C,E

10.03.2022

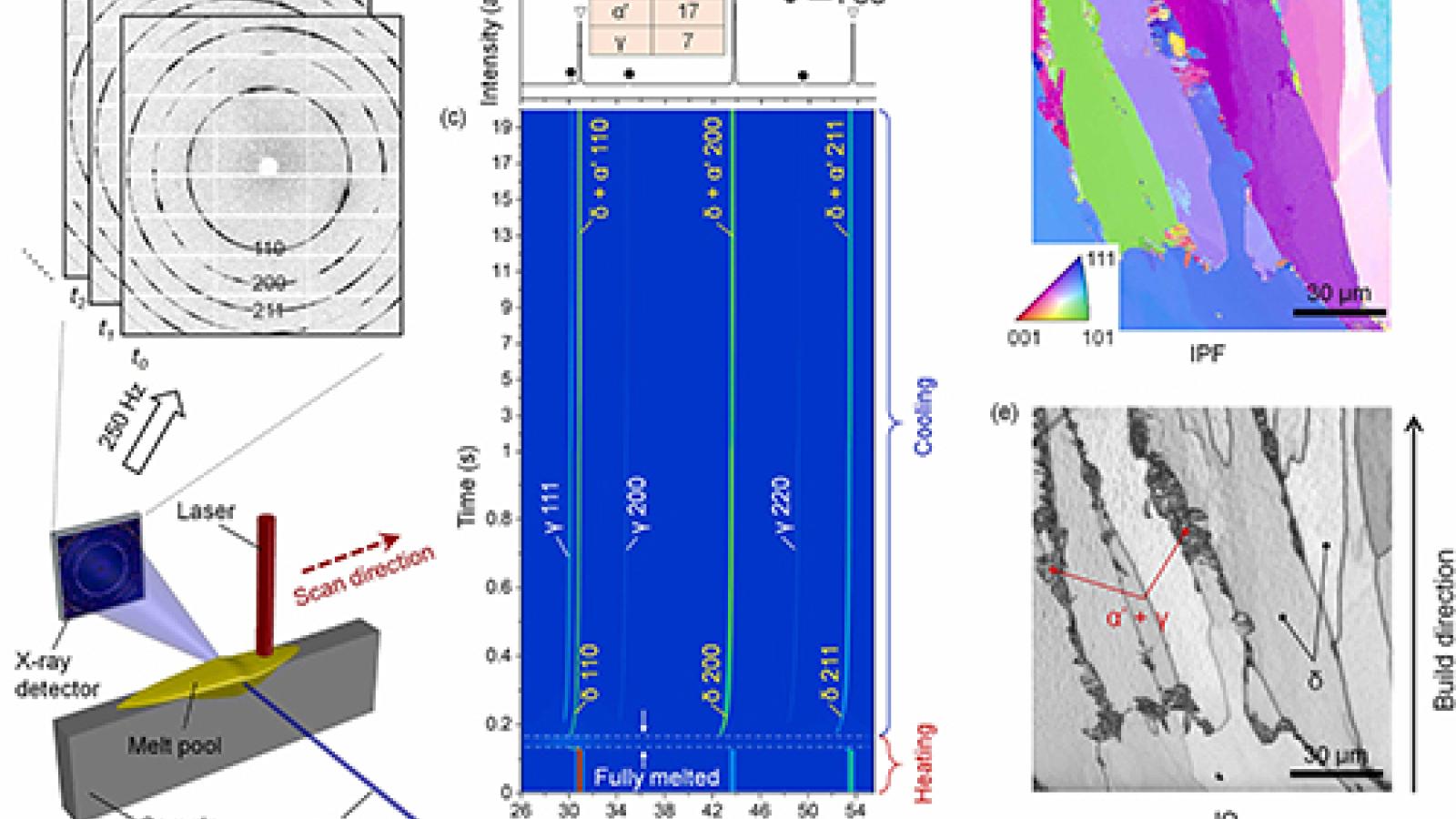

How to 3D-Print One of the Strongest Stainless Steels: Many critical technologies contain a remarkably strong and corrosion-resistant alloy called 17-4 precipitation hardening stainless steel. Based ...

1-ID-B,C,E, 9-ID-B,C

11.14.2022

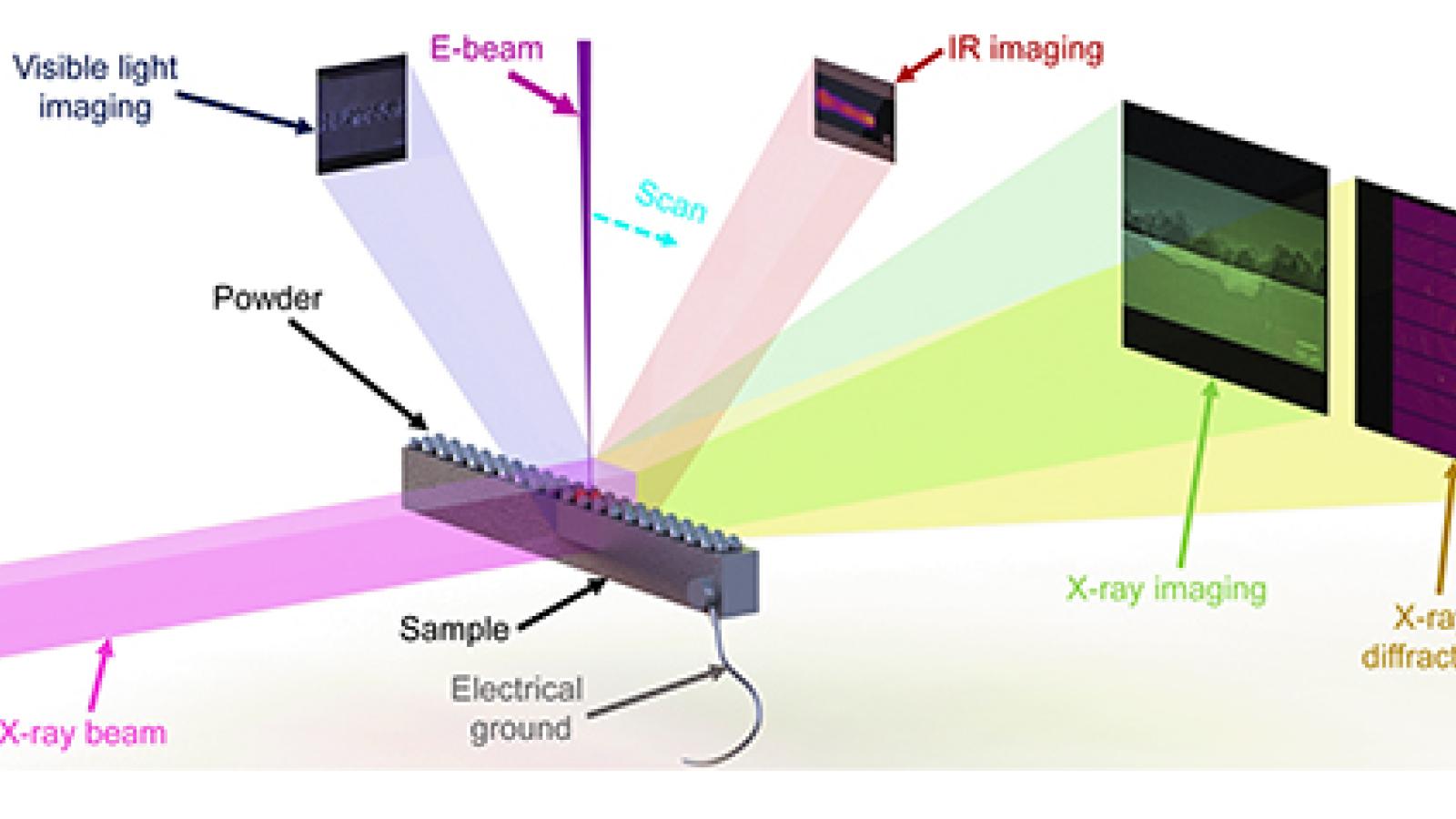

New System to Visualize 3-D Metal Printing Process May Tap Its Unrealized Potential: The additive manufacturing technique electron beam-powder bed fusion (EB-PBF) has grown rapidly in recent years. R...

1-ID-B,C,E, 32-ID-B,C

01.30.2023

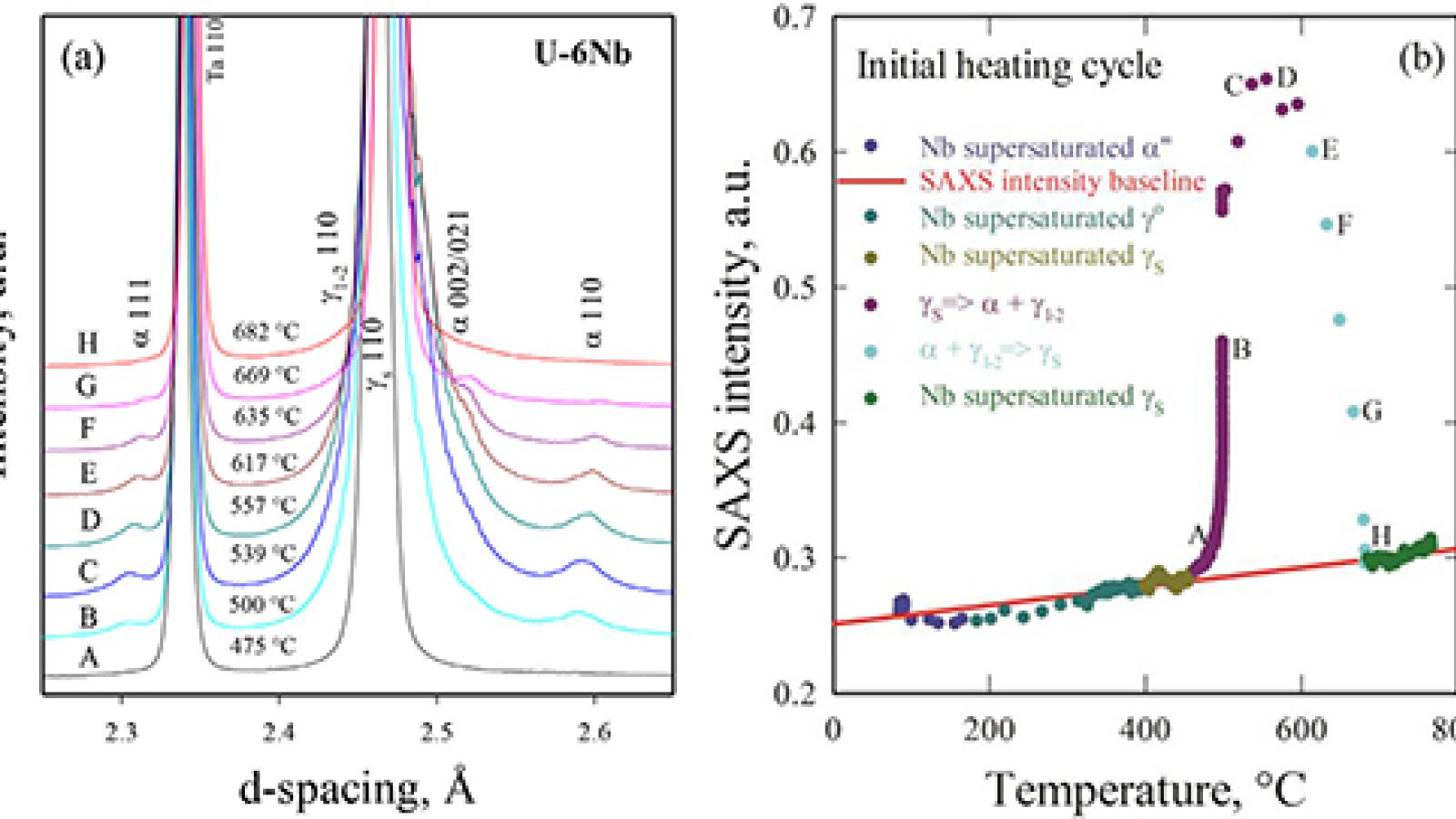

The More Things Change, the More They Become the Same in Uranium-Niobium: Experimenters used synchrotron x-ray studies at the U.S. Department of Energy’s Advanced Photon Source to investigate the ...

1-ID-B,C,E