We all know that it's important to relax once now and then, but sometimes the way in which it is done makes a big difference. That's the case with technologically valuable soft materials that undergo dynamic arrest such as gels, glasses, and emulsions, and which display very complicated relaxation behavior. A team of investigators used the U.S. Department of Energy’s Advanced Photon Source (APS) for their studies of the detailed microscopic dynamics of relaxation in a model soft gel, establishing a previously elusive connection between the rearrangement events occurring on the microscopic scale and the observable stress relaxation behavior on the macroscale. The work, published in the Proceedings of the National Academy of Sciences of the United States of America, provides a deeper understanding of the origins of the microscopic motions inside soft materials, and their connection to macroscopic physical properties such as the “softness” of a gel.

One of the major challenges in studying the microscopic motion of particles inside soft materials has been the phenomenon of “rheological aging”. This is a process in which the constant thermal motion of the constituent particles causes a slow change in the internal structure and thus the property of a material (for a familiar example of this, consider the yogurt in your fridge which gradually expels a watery layer as it ages and becomes stiffer and denser, a process also known as syneresis). Aging processes are known to produce highly complex microscopic dynamics inside soft materials that mask the motion of particles in their stationary or “quiescent” states. Thus, the research team designed a soft gel material in which this aging effect was suppressed, and this allowed them to study the internal motions of the gel in a quiescent state as well as in response to controlled perturbations.

To study this model gel material, the researchers combined rheological studies with ultra-small angle x-ray scattering (USXAS) at the APS X-ray Science Division (XSD) Chemical & Materials Science’s Group’s 9-ID beamline and x-ray photon correlation spectroscopy (XPCS) at the XSD Dynamics & Structure Group’s 8-ID-I beamline also at the APS, an Office of Science user facility at Argonne National Laboratory. Synchrotron x-ray scattering techniques avoid the limitations of visible-light studies and provide a key advantage for the team’s research due to the high electron density contrast between the nanoparticles, polymers, and water medium.

The fact that many soft materials show a complex broad distribution of stress relaxation times when viewed from the macroscopic perspective is well-established (and is also displayed in the team’s non-aging sample). However, the connection of these observations to microscopic-scale relaxation behaviors has been hard to pin down. To address this, the team performed XPCS studies on a quiescent material gelled in a capillary in situ and demonstrated that “superdiffusive” dynamics were prevalent throughout the microstructure, i.e., material elements in the relaxing gel moved faster than that predicted by the classical law of Fickian diffusion. This signified the release of internal stresses built up in the gel during dynamic arrest.

By carefully comparing measurements over a range of temperatures, the team found that the timescale of this superdiffusive process was equivalent to the mean timescale of macroscopic stress relaxation in the gels, a result consistent with the idea that the microscopic origins of stress relaxation lie in the constant rearrangements occurring inside the microstructure which are dictated by internal states of stress. They also showed that these stresses are anisotropic, resulting in faster relaxation processes near the walls constraining the gel which prevent the relaxation of internal stress during gelation. Overall, these observations confirm that trapped local stresses within the gel clusters drive relaxation at macroscopic scales as well.

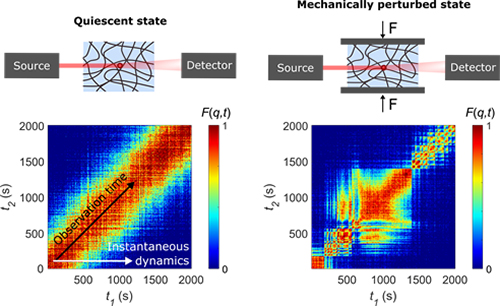

The team also found that the microscopic relaxation times of the gel in the quiescent state exhibited a Gaussian distribution, which was inconsistent with the complex non-Gaussian distribution of stress relaxation times observed macroscopically. Therefore, the investigators decided to check for perturbation-induced effects on the macroscopic relaxation process. To do so, the team induced an approximately 10% compressive strain on the gel sample inside an aluminum cell holder and performed XPCS on these compressed gels. The team found that the compressed gel exhibited significantly different microscopic dynamics than was observed in the quiescent state. Whereas the quiescent state resulted in temporally homogeneous relaxation dynamics, the perturbed state resulted in highly intermittent instantaneous dynamics (Fig. 1). By tracking the distribution of intermittent fluctuations in the perturbed sample, the team found that the fluctuations exhibited highly non-Gaussian statistics at short times (in a similar vein to the non-Gaussian distribution of stress relaxation times observed at the macroscopic scale) before reverting to Gaussian statistics at longer time scales approaching the mean microscopic relaxation time. This shows that quiescent internal stress relaxation is not enough to account for the broad range of stress relaxation processes in these arrested soft materials, because some form of perturbation at the microscale is required to trigger a broader distribution of stress relaxation times.

With these experiments, the team has demonstrated a link between the very small and the very large worlds of dynamically arrested soft materials. What may appear to be simple linear viscoelastic behavior on the macroscale is governed by a complex set of dynamical behaviors at the microscale. The researchers suggest that combining in situ measurements of microscopic relaxation processes induced by other types of small-scale perturbation events together with bulk macroscopic stress relaxation behavior (especially with the imminent arrival of higher-intensity x-rays from the upgraded APS) could reveal even more intriguing insights into physics of arrested soft materials. ― Mark Wolverton, Jake Song, and Gareth H. McKinley

See: Jake Song1, Qingteng Zhang2, Felipe de Quesada1, Mehedi H. Rizvi3, Joseph B. Tracy3, Jan Ilavsky2, Suresh Narayanan2, Emanuela del Gado4, Robert L. Leheny5, Niels Holten-Andersen1*, and Gareth H. McKinley1**, “Microscopic Dynamics Underlying the Stress Relaxation of Arrested Soft Materials,” Proc. Natl. Acad. Sci. U.S.A. 119 (30) e2201566119 (2022). DOI: 10.1073/pnas.2201566119

Author affiliations: 1Massachusetts Institute of Technology, 2 Argonne National Laboratory, 3North Caroline State University, 4Georgetown University, 5Johns Hopkins University

Correspondence: * [email protected], ** [email protected]

The authors acknowledge funding from the National Science Foundation (CBET-1605943, CBET-1605699, CBET-1804721, 493 DMR-1419807), the U.S. Army Research Office (through the Institute for Soldier Nanotechnologies under Contract No. 495 W911NF-13-D-0001), and the U.S. Department of Energy (DOE) (through Argonne National Laboratory under Contract No. 497 DE-AC02-06CH11357). This research used resources of the Advanced Photon Source, a U.S. DOE Office of Science user facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357.

The U.S. Department of Energy's APS at Argonne National Laboratory is one of the world’s most productive x-ray light source facilities. Each year, the APS provides high-brightness x-ray beams to a diverse community of more than 5,000 researchers in materials science, chemistry, condensed matter physics, the life and environmental sciences, and applied research. Researchers using the APS produce over 2,000 publications each year detailing impactful discoveries, and solve more vital biological protein structures than users of any other x-ray light source research facility. APS x-rays are ideally suited for explorations of materials and biological structures; elemental distribution; chemical, magnetic, electronic states; and a wide range of technologically important engineering systems from batteries to fuel injector sprays, all of which are the foundations of our nation’s economic, technological, and physical well-being.

Argonne National Laboratory seeks solutions to pressing national problems in science and technology. The nation's first national laboratory, Argonne conducts leading-edge basic and applied scientific research in virtually every scientific discipline. Argonne researchers work closely with researchers from hundreds of companies, universities, and federal, state and municipal agencies to help them solve their specific problems, advance America's scientific leadership and prepare the nation for a better future. With employees from more than 60 nations, Argonne is managed by UChicago Argonne, LLC, for the U.S. DOE Office of Science.

The U.S. Department of Energy's Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit the Office of Science website.